stage 2: when you are aware of the diameter, use the system described earlier mentioned to compute the burden of the TMT Bar per meter or for each piece.

Purging and Refining: The molten steel is purged within the ladle furnace in advance of numerous refining chemicals are introduced to remove any leftover impurities. These agents as well as other substances assist in accomplishing the necessary chemical composition and enhancing steel quality.

The development of calcium carbonate lowers the pH price of metal So which makes it much more susceptible to corrosion. The corroded products are detrimental simply because they tend to be more voluminous and exert force from the concrete leading to cracking. To protect metal from corrosion CRS TMT was launched to prolong the longevity of RCC framework.

In addition to energy, TMT bars have excellent ductility and elongation Homes. Ductility refers to the capacity of a fabric to deform under strain with out fracturing. TMT bars can go through substantial deformation ahead of reaching their breaking position, which helps prevent sudden failure and guarantees the security of constructions.

to make certain TMT bars meet specific high-quality and general performance standards, they are graded and regulated As outlined by field specifications.

correct dimensions are vital in construction, as they immediately influence the match and steadiness of the construction. TMT bars will have to conform to dimensional tolerances specified in sector criteria. These tolerances relate to parameters like diameter, size, and body weight for each meter.

Strength and Durability Advantages: TMT bars drastically bolster the power and toughness of reinforced concrete constructions, leading to extended assistance life.

This allows in assessing the corrosion resistance of said TMT bar. typically, this technique is coupled with other approaches to perform elaborate exams and acquire a comprehensive idea of the corrosion mechanisms affecting the TMT metal bars.

Regardless of the greater toughness, Fe550 maintains a equilibrium amongst energy and ductility, making certain toughness from worry.

SRMB CRS TMT Bar is produced by adding alloying features like Cr, Cu, Ni, Mo and P, possibly separately or together, to improve allied product or service Qualities. In the electrical Furnace, corrosion resistant things like phosphorus, copper/chromium are extra on the molten steel, although carbon and sulphur is lowered even further through refining and deslagging.

try to find companies that deliver the most effective TMT bars in Kerala. you desire to make sure that the bars you end up picking are of top quality and meet up with marketplace requirements. look for the standing on the company, and skim buyer reviews to gauge their trustworthiness.

Corrosion Resistance take a look at: This certain take a look at evaluates the capacity of TMT bars to face up to corrosion, a significant factor in determining their prolonged-phrase toughness. It assesses their resistance to moisture, chemical substances, and several environmental aspects that will likely set off corrosion.

Thermo Mechanically addressed metal or TMT bars offer you an excellent mix of malleability and ductility. Among the many four kinds of reinforcement steels, TMT is considered Among the most top-quality ones. The reason remaining, that TMT fulfills the normal toughness and toughness necessities of building activities quite competently.

Epoxy Coatings: utilize epoxy-dependent coatings within the surface area of TMT bars to make a barrier versus humidity and corrosive brokers. These coatings present great adhesion and safeguard the bars from the ecosystem.

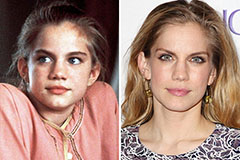

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!